Bag-on-Valve Packaging: What Is It?

Definition of Bag-on-Valve Packaging

Bag-on-Valve (BOV) is a barrier packaging system that keeps the product and the propellant completely separate. This design preserves product purity, offers longer shelf life, and ensures smooth and continuous dispensing in any position.

Bag-on-Valve is based on an ingenious dispensing system:

- A bag is attached to the valve inside the can.

- An eco-friendly propellant (compressed air or nitrogen) is added outside the bag (between the bag and the can walls).

- The product is filled inside the bag, never touching the propellant.

How Bag-on-Valve Packaging Works

When you press the actuator, the eco-friendly propellant (compressed air or nitrogen) squeezes the bag, pushing the product out without mixing with the gas.

This ensures steady and precise dispensing of the product for an optimal and user-friendly experience.

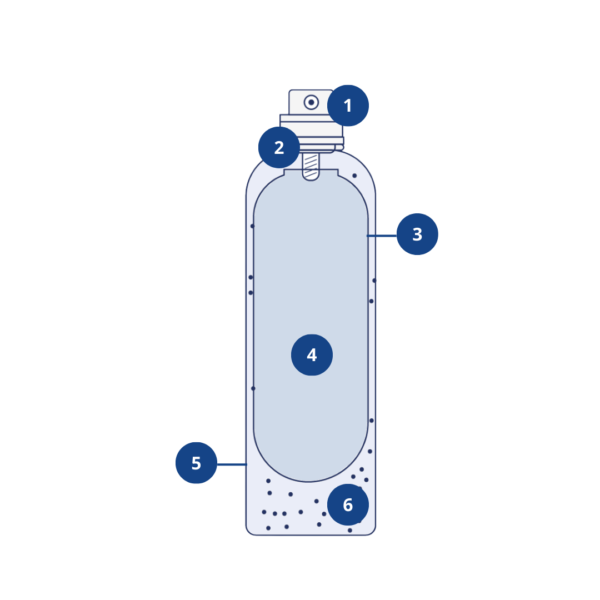

Main Components of a BOV Packaging System

- Actuator: With or without overcap; designed for easy handling and to control the spray experience.

- Valve: Male or female type, providing secure sealing and regulating the flow from the bag.

- Barrier Bag:

- Multi-layer bag (PP or PE/OPA/Alu/PET) for traditional BOV designs.

- Monomaterial PET bag, Power Container Corp.’s innovation for improved reliability and robustness, and with lower environmental impact.

- Customer Product / Formula: Filled into the bag to remain isolated from the propellant.

- Aerosol Can: Aluminium, tinplate, or plastic; standard or custom-shaped.

- Propellant: Compressed air or nitrogen; filled in the space between the bag and can.

Why Use Bag-On-Valve Packaging?

Preserves Product Purity

Because the product is completely isolated inside the bag and never comes into contact with the propellant gas, Bag-on-Valve packaging ensures that formulas remain uncontaminated and maintain their original quality throughout their entire lifespan. This is especially important for sensitive products like cosmetics, pharmaceuticals, and food.

Reliable Dispensing from Any Angle

The design allows for 360° use, meaning you can spray or dispense the product even when the can is upside down or tilted. This flexibility improves user experience and reduces product waste, as you can access nearly every last drop.

Extended Shelf Life and Stability

By preventing contact with air or chemical propellants, the bag protects the product from oxidation and contamination. This barrier helps maintain product integrity longer, ensuring freshness and efficacy over time.

Eco-Friendly and Sustainable

Bag-on-Valve systems often use compressed air or nitrogen as propellants instead of harmful chemicals, making them safer for the environment. At Power Container Corporation, we have engineered an exclusive monomaterial PET pouch for our BOV solutions, enhancing sustainability goals.